Advantages of machining cast iron turning insert SNMA120408

Cast iron is a common structural material widely used in the automotive, machinery, mold and other industries.

But it is also a “difficult” material: high hardness, high brittleness, high carbon content, and easy to cause problems such as chipping, chip sticking, and intermittent cutting during processing. Therefore, choosing a suitable blade is particularly important.

At this time, the SNMA120408 turning blade plays its true value.

It is a blade designed for roughing and high-load cutting, and performs particularly well when processing materials such as gray cast iron and ductile iron.

What is SNMA120408?

Let’s quickly understand the meaning of this blade model:

S: square blade, with 4 corners available (single side)

N: 0° back angle, strong rigidity

M: medium precision grade

A: without hole, often used with pressure plate type tool holder

120408: indicates 12mm side length, 4.76mm thickness, 0.8mm fillet radius

In other words, SNMA120408 is a turning blade with extremely stable structure, suitable for heavy load, high rigidity rough machining, especially in cast iron working conditions, and can withstand large cutting forces and impact forces.

SNMA120408 Four core advantages of machining cast iron

1. Super rigidity, especially suitable for rough machining

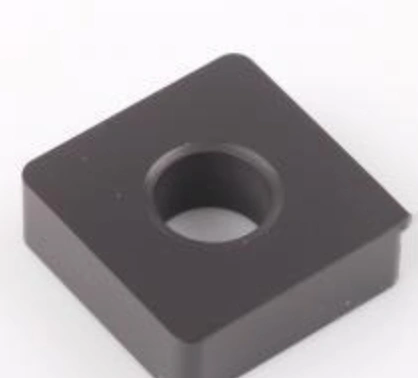

SNMA is a square blade, each blade tip has a larger support area, which can effectively absorb the impact force during machining.

2. High wear resistance + large radius design, more resistant to collapse

SNMA120408 generally uses a cemented carbide substrate (such as K10, K20 grade) specially used for cast iron machining, with a Vickers hardness of HV above 1800, and combined with CVD coating (such as TiCN + Al₂O₃), which is not only wear-resistant but also resistant to high temperature.

3. Smooth chip breaking and stable cutting

Although SNMA does not have a standard chip breaker, we can effectively control the chip shape by optimizing the machining parameters (such as feed rate and cutting speed). After matching the cast iron special material recommended by our factory, the chips are neat, there is no sticking phenomenon, and the cutting process is more stable.

4. Single-sided 4-tip cutting edge, economical and practical

Each piece of SNMA120408 can use 4 cutting edges. Although it is not as “multi-tip” as the double-sided design, its strength and stability make up for it, making it more suitable for cast iron turning scenarios where “wear resistance is king”.

So what materials are suitable for TNMG?

Many customers often ask: “I used TNMG before, can it replace SNMA?”

Let’s compare:

| type | Insert structure | Number of available cutting edges | Strength performance | Applicable working conditions |

| TNMG | Equilateral triangle, two-sided | 6个 | medium | Suitable for finishing of steel, stainless steel, continuous cutting, etc. |

| SNMA | Square, single-sided | 4个 | Very high | It is particularly suitable for rough machining of cast iron, intermittent cutting and other scenarios |

Conclusion: If you are doing rough machining, external turning of castings, or even intermittent cutting with stability as the priority, SNMA120408 is more suitable.

Why choose SNMA120408 from our factory?

Choose the right blade, and choose the right supplier. In the field of cemented carbide, our advantages are not only reflected in products, but also in services:

Full-process self-owned production line: From raw material powder making to sintering, coating, grinding, the whole process is self-controlled, and the quality is more controllable

Multiple materials are available: For gray cast iron and ductile iron, we provide K10/K20 and other material formulas

Sufficient inventory and fast delivery: SNMA120408 is a year-round stock model and can be shipped on the same day

Support non-standard customization and OEM services: can mark according to customer needs, customize packaging, switch non-standard sizes

Rich experience in international services: support English, Spanish, Russian, Arabic customer communication, export to 20+ countries around the world