Puwei Carbide Cutter Inserts: Born for Turning Stainless Steel

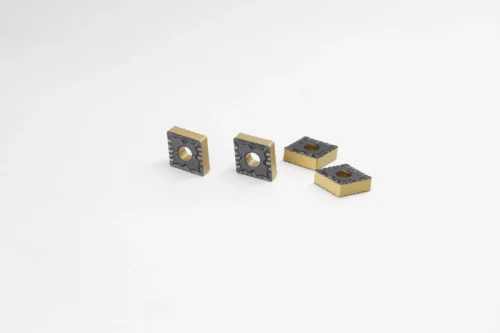

In the field of metal processing, carbide cutter inserts also called Tungsten carbide insert have always been a “weapon” for efficient cutting.

As a company specializing in the research and development of carbide tools, Puwei is well aware of the stringent requirements of turning on the blade performance – especially when facing difficult-to-process materials such as stainless steel, it is necessary to ensure cutting efficiency and take into account tool life.

Today, we will explain to you how to use the right turning inserts to easily solve the problem of stainless steel turning!

Why are Puwei’s carbide cutter inserts trustworthy?

1. Super wear resistance, double life

Puwei carbide inserts use high-purity tungsten carbide cutter insert substrates and advanced coating technology (such as TiAlN, PVD coating), with a hardness of HRA 92 or above, which can easily cope with the high stickiness of stainless steel chips and work hardening problems, greatly reducing the time cost of frequent tool changes.

2. Sharp cutting, smooth surface

In view of the characteristics of stainless steel, we have optimized the geometric angles of carbide cutter inserts (such as rake angle, chip breaker design), with lower cutting resistance, effectively avoiding material sticking to the tool, making the machined surface smoother, and reducing secondary polishing processes.

3. carbide cutter insert Flexible adaptation, one “piece” for multiple uses

Whether it is rough machining or fine turning, Puwei carbide turning inserts (Inserts for Turning) provide a variety of tool tip radius (R0.2-R1.2) and edge treatment solutions to adapt to different working conditions and allow your machine tool to maximize its potential.

Puwei recommends: stainless steel turning insert model

carbide cutter insert CNMG120404-MS:

Applicable scenarios: 304/316 stainless steel rough turning, intermittent cutting

Advantages: thick coating + strong substrate, strong impact resistance, suitable for large feed processing.

Tungsten carbide insert WNMG080404-MS

Applicable scenarios: precision turning of medical grade stainless steel parts

Advantages: ultra-fine grain substrate + mirror coating, achieving surface roughness within Ra0.8.

carbide cutter insert TNMG160404-MS

Applicable scenarios: deep hole turning or low rigidity working conditions

Advantages: sharp positive rake angle design, light cutting, reduced vibration.

Carbide Cutter Insert has always been committed to “making machining easier”. If you are troubled by the low efficiency and high cost of stainless steel turning, why not try our customized solutions