Carbide insert nomenclature: accurate identification, efficient selection

As a carbide insert manufacturer, we know that clear product naming rules are very important to customers. Our carbide insert naming system is scientifically designed to convert complex parameters into concise codes to help you quickly identify and accurately select models. The following is an analysis of the core logic and advantages of this naming system:

Why choose our naming convention?

The parameters are clear at a glance:

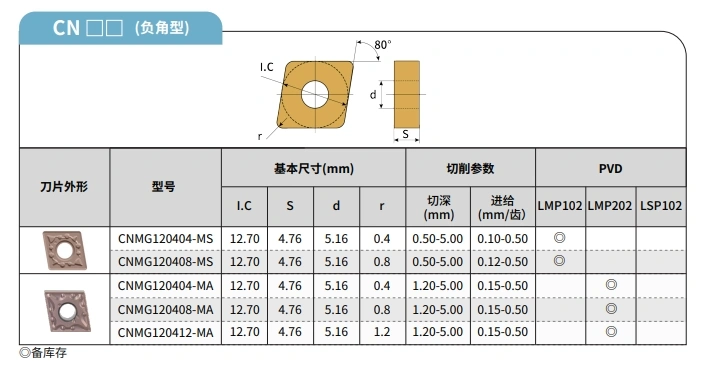

We give each set of characters a clear meaning, covering key information such as insert shape, back angle, tolerance, type, size, edge treatment, etc. For example, we can break down the code CNMG120408 into:

C: Diamond 80° insert shape

N: Back angle is 0°

M: Tolerance grade is ±0.08mm

G: Blade with wiper edge

12: Cutting edge length 12mm

04: insert thickness 4.76mm

08: insert tip radius 0.8mm

How to interpret the nomenclature?

We use the first four letters to define the geometric features, use the last six digits to indicate the dimensional parameters, and use the suffix code (such as MA/MSWe give each set of characters a clear meaning, covering key information such as insert shape, back angle, tolerance, type, size, edge treatment, etc. For example, we can break down the code CNMG120408 into:) to identify customized properties such as material and coating.

Our nomenclature empowers your business

Quickly respond to needs: When customers provide a code, we can immediately retrieve the corresponding product specifications, shortening the delivery cycle.

Reduce human errors: Standardized codes replace lengthy descriptions to avoid selection confusion and improve order accuracy.

Strengthen brand professionalism: The unified naming system demonstrates technical strength and wins customer trust.