The difference between End Mill Sharpener and End Mill Grinder

In the field of machining, the End Mill Sharpener and the End Mill Grinder/Milling Machine are two devices with completely different functions and are often confused because of their similar names

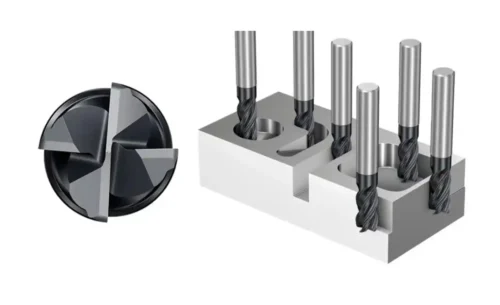

End Mill Sharpener: mainly used for grinding the end mill that has been worn and restoring its cutting performance. Usually has a precision fixture and grinding wheel, suitable for specific types of cutting edge repair, such as end edge, peripheral edge, ball, etc.

End Mill (referring to end mill or end mill) : If the “Grinder” here refers to a grinder, it may have a similar function to sharpener, but if it is an “end mill”, it refers to a machine tool that performs milling, such as an ordinary milling machine, but the user may have confused the term.

First, the core difference of equipment

| sort | End Mill Sharpener | Milling Machine |

| Core function | End milling cutter designed to repair wear, restoring sharpness and geometric accuracy of its cutting edge. | It is used for milling the workpiece (such as plane, groove, surface, etc.). |

| Application scenario | Tool maintenance and refurbishment to extend tool life. | Metal, wood, plastic and other materials cutting molding processing. |

| Structural characteristics | Equipped with precision grinding wheel, Angle adjustment device and tool fixture, the operation is mainly grinding. | The spindle drives the milling cutter to rotate, and the table can move in multiple axes to support a variety of milling processes. |

| Processing object | Cutting tools (such as end mills, ball knives, etc.). | Workpieces (such as mold parts, mechanical structures, etc.). |

Second, adaptive tool recommendation

| Processing demand | Recommended milling cutter type |

| Face milling | Face milling cutter (indexable blade type), multi-edge end milling cutter |

| Groove/side wall finishing | Keyway milling cutter, T-slot milling cutter, long edge end milling cutter |

| Surface /3D outline | Ball end mill, round nose mill |

| High efficiency roughing | Corn milling cutter |

End milling machine and end milling machine focus on tool repair and workpiece machining respectively

which together can significantly improve processing efficiency and cost control. The correct selection and standard operation of the tool is the key to ensure the machining accuracy and extend the life of the equipment.

It is recommended to flexibly combine equipment and tools according to material characteristics, processing needs and budget to achieve maximum benefit.