Square end milling cutter and flat end mill

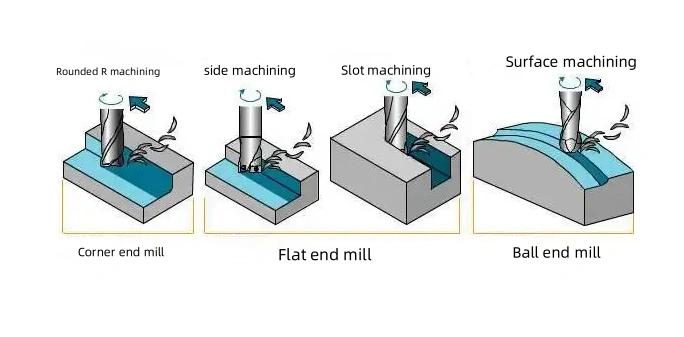

When we consider Straight End Mills (also known as Square End Mills), we can describe their edge characteristics like this: We design the end of the cutter teeth to be a right square, and we make the cutting edges on both sides symmetrical. Usually, we adopt a double – edge design, which enables us to use them for processing right – angle profiles.

Typical use: Specially used for machining keyways, right Angle grooves and other scenes requiring strict dimensional coordination, such as drive shaft keyway processing

Key performance comparison:

| Comparison item | Square end milling cutter | Flat end mill |

| Axial feed capability | Vertical cutting (like drill) | Direct axial feeding is not possible, requiring spiral or oblique cutting |

| Tooth number design | Most of them are double-edged, large chip-holding slots, suitable for heavy cutting | 2-4 blades, both efficiency and surface quality |

| Machining accuracy | Keyway width tolerance can be controlled within ±0.02mm | The flatness error is generally ≤0.05mm |

| Tool rigidity | The short edge design enhances vibration resistance and is suitable for deep groove machining | Long edge type is easy to flutter, need to control the cutting depth |

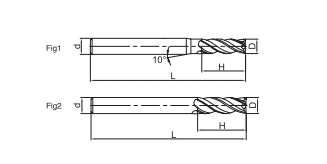

What is a long edge end mill

The long edge end mill serves deep cavity machining with a blade length 2-3 times longer than standard end mills, earning the title ‘deep exploration tool’ in mold processing.

The blade length of the long edge end mill is longer than the blade length of the flat end mill, so you can use the long edge end mill to process to a deeper depth compared to the flat end mill. You should select the end mill according to different processing scenarios.

Long edge end mill application scenarios: deep cavity mold processing, aerospace parts, medical equipment manufacturing

What are the advantages of a long edge end mill and a flat end mill

1. Advantages of deep cavity processing:

The long edge end mill can have a blade length up to 10 times the diameter, and you can directly process the deep cavity mold or box parts without changing the tool halfway.

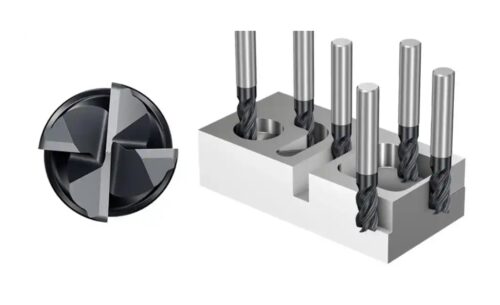

2. Cutting stability performance:

We optimize the core thickness to ensure that the long edge end mill maintains rigidity while increasing the chip removal space. The long edge end mill also has a shock – proof design advantage: its special spiral angle can reduce the resistance when cutting the workpiece, and it can reduce the vibration by 40% during the actual processing of HRC60 die steel.

3. Comparison of processing efficiency:

Long edge end mill, in the mobile phone shell mold processing, the long edge knife can complete the 15mm bone position processing at one time, and the efficiency is 3 times higher than the flat head.

4. Long edge end mill special field adaptability

Long blade knife with CBM coating, processing HRC60 hardened steel life is 4 times that of flat blade

Flat end milling cutter is more suitable for surface milling and square shoulder machining.

Through the comparison of flat end long edge end mill and head end mill, we understand that long edge end mill can process deep cavity mold, the cutting performance and processing efficiency of this end mill will be better than flat end mill, but if it is not processing deep cavity mold, it is necessary to choose flat end mill oh ~