Puwei carbide turning insert model comparison table

As a professional manufacturer with many years of experience in cemented carbide turning insert field, Puwei is well aware that the core of efficient processing lies in the precise matching of tools.

To help you quickly locate the ideal turning insert solution, we have carefully created three core chart tools based on industry needs – Carbide Insert Chart, Insert Identification Chart and Lathe Insert Chart, making the complex selection process simple.

1、Lock the processing range

With our Carbide Insert Chart, you can get the geometric parameters and performance data of the entire series of turning inserts at the click of a button. Whether it is the tip radius, edge inclination, or chip breaker design, the chart is clearly presented in a graded comparison form to help you quickly select the insert model that is suitable for the workpiece material (such as steel, cast iron, stainless steel) and processing type (roughing/finishing).

2、Accurate identification

Confused by the alphanumeric combination of insert model codes? Our Carbide Insert Identification Chart.

This chart systematically parses ISO standard coding rules, breaking down key information such as material grade, edge treatment, tolerance grade, etc. bit by bit.

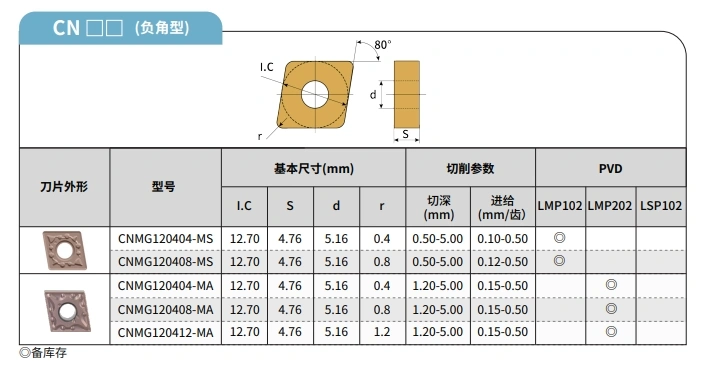

For example, in the code “CNMG120408-MA”, “C” represents the insert shape, “N” indicates the back angle, and “MA” refers to the double-sided chip breaker design

3、Strengthen working condition matching

In response to the special needs of turning processing, Puwei Lathe Insert Chart Puwei further refines the application scenarios.

The chart is classified by processes such as external cylindrical turning, end cutting, grooving and cutting, and combines the spindle speed, feed rate, and cutting depth parameters to recommend the optimal insert-tool bar combination.

For example, under high-intensity intermittent cutting conditions, the chart will give priority to guiding you to choose negative inserts with enhanced cutting edges to ensure processing stability. In addition, the chart also marks coolant adaptation suggestions to help you fully optimize processing conditions.