Product Name:turning insert

|

Brand : |

PUWEI |

|

End Mills specifications: |

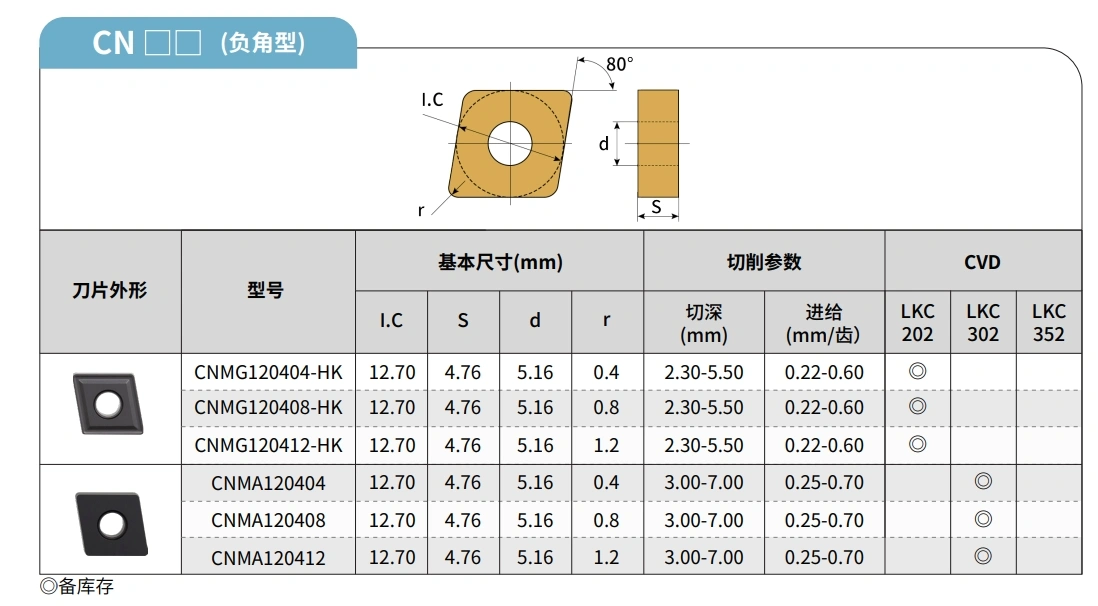

CNMG-HK |

|

Coating: |

CVD |

|

End mill product material: |

Tungsten steel |

|

Spiral Angle: |

35° |

|

Yieldly: |

ZhuZhou,HuNan,China |

Puwei turning insert CNMG-HK product details

Puwei’s CNMG-HK turning insert is mainly used to process cast iron, while the turning inserts CNMG-PV\CNMG-43\CNMG-TM\CNMG-MA are all used to process steel parts. This is the distinction Puwei makes in terms of models.

This type of product has high hardness and strength, good wear resistance and thermal stability, and excellent chip breaking performance.

CNMG -HK product adavantages

TCNMG – HK turning inserts are usually made of cemented carbide, which has extremely high hardness and wear resistance.The manufacturing precision of the blade is high, the geometric shape accuracy of the cutting edge is high, and it has high-precision processing capabilities

CNMG-HK product disadvantages

Not suitable for processing some special materials: Although CNMG-HK turning inserts can adapt to the processing of many common metal materials, the processing effect may not be ideal for some special materials, such as nickel-based alloys and cobalt-based alloys with high melting points and high hardness.

carbide turning insert Product Details

CNMG – HK turning inserts excel in machining performance. The cutting edge is carefully designed, and the unique geometry can effectively reduce cutting forces, achieve stable cutting at high cutting speeds, and greatly improve cutting efficiency.

lathe insert chart车床刀片图表