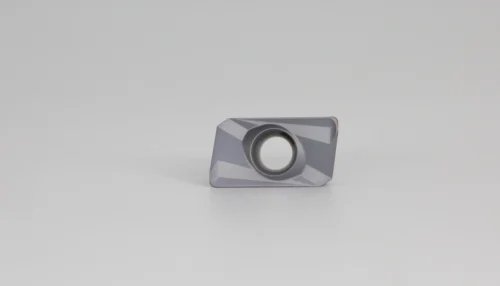

Product Name:Milling inserts-aPMT

|

Brand : |

PUWEI |

|

End Mills specifications: |

APMT1604PDER |

|

Coating: |

PVD |

|

End mill product material: |

Tungsten steel |

|

Spiral Angle: |

35° |

|

Yieldly: |

ZhuZhou,HuNan,China |

Puwei milling inserts-aPMT details

APMT1604 is a common type of milling inserts named in accordance with ISO standards, with each letter and number representing the specific parameters and characteristics of the insert.

milling inserts-APMT product adavantages

High hardness and high strength: carbide material is usually used, the hardness can reach HRA90 or more, much higher than high-speed steel and other alloy steel, with high bending strength and compressive strength.

High precision machining: high manufacturing precision, straight cutting edge, sharp, can ensure that the surface roughness of the workpiece after processing to meet the requirements

1、Model Analysis (APMT1604PDER)

A: The insert shape is 85° diamond (cutting edge Angle is 85°), suitable for general milling.

P: The rear Angle of the insert is 11°, providing good chip removal performance and cutting sharpness.

M: Tolerance level (accuracy level), which affects the repeated positioning accuracy of the insert installation.

T: insert type (fixed), usually indicating a center hole or a specific chip breaker design.

16: Cutting edge length is 16 mm.

04: inserts thickness is 4 mm.

2 、切削参数参考

| argument | Rough finish | finishing |

| Cutting speed (Vc) | 80-200 m/min | 150-300 m/min |

| Feed (fz) | 0.1-0.3mm/tooth | 0.05-0.15 mm/tooth |

| Depth of cut (ap) | 2-5 mm | 0.1-1 mm |

VNMG160404-MA steel turning inserts

VNMG160404-MA steel turning inserts When turning steel parts, choosing the right blade not only affects the cutting effect, but also has a direct impact on cost and processing efficiency. Especially for those workpieces with high precision requirements such as slender shafts, stepped parts, chamfered inner holes, etc., ordinary blades are often unable to meet the…

Advantages of SNMG120408-MA turning insert for machining steel parts

Advantages of SNMG120408-MA turning insert for machining steel parts In the field of turning, choosing the right blade directly affects efficiency and cost. SNMG120408-MA is a stable and reliable negative rake blade that performs very well in steel processing and is the preferred blade model for many processing plants in mass production. So, what are…

Advantages of TNMG160404-PV steel turning insert

Advantages of TNMG160404-PV steel turning insert In daily steel processing, it is very important to choose an efficient, stable and durable blade. TNMG160404-PV is a classic steel turning insert model designed for light-load finishing and semi-finishing of steel parts. If you are looking for a blade with smooth cutting, high cost performance and strong adaptability,…