Explore the type of milling cutter: milling machine cutter big secrets

Types of milling cutter:

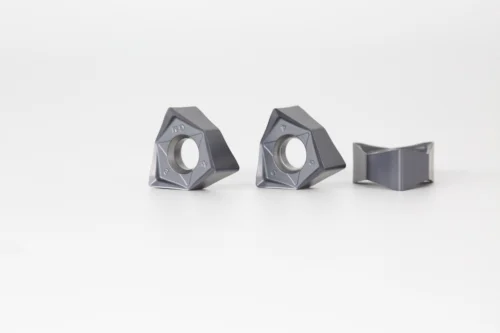

There are many types of milling blades,

divided into face milling blades,

square shoulder milling blades,

fast feed blades,

copy milling blades and corn milling blades.

milling blade differences:

| Type | structure | Cutting edge | Application scenario |

| Face milling inserts | Round or triangular in shape, | The circular blade has multiple cutting edges and can realize multi – direction cutting. The manufacturer designs triangular blades to generally have three relatively short cutting edges. | This tool is mainly used for surface milling processing. It can mill various parts of the plane, step surface, etc. It is suitable for processing a large – area plane and can effectively improve the processing efficiency. |

| Square shoulder milling blade | Square or diamond shape | The blades have four cutting edges, and the manufacturer specially designs the corners of the blades to produce 90° right – angle shoulders. | We often use it for processing parts with right shoulders, such as the intersections of the side walls and the bottom surfaces of boxes, molds, etc., to ensure the accuracy and surface quality of the processed right shoulders. |

| Fast forward to the blade | Shapes are more diverse, common triangle, quadrilateral and so on | The cutter has a unique cutting – edge design. It usually has a large feed coefficient and can maintain good cutting performance at high feed speed. | We can use it for processing occasions that require high feed speed. For example, in fields like automotive parts manufacturing and aerospace, we can use it for efficient roughing and it can remove a large amount of material in a short time. |

| Copy milling cutter blade | According to different copying processing needs, the shape is different | It takes an irregular curved shape or a special special – shaped structure to adapt to the processing of complex surfaces. | We mainly use it in fields such as mold manufacturing and impeller machining that need to process complex surfaces, and we can accurately copy it according to the outline shape of the parts. |

| Corn milling blade | It is usually spiral or cylindrical | The blade has multiple cutting teeth. It is similar in shape to a corn cob, and the cutting edges are distributed on its cylindrical surface. | We often use it for deep – slot milling, large – margin cutting, and occasions with high processing – efficiency requirements, such as in heavy machining and mining machining. We can use it for milling deep holes and deep slots. |

Milling machine tool:

The milling machine tool refers to the tool blade used for cutting on the milling machine,

and which can process the workpiece

so with various shapes and accuracy to meet different production needs by cooperating with the milling machine.

What is a horizontal milling cutter

Horizontal milling cutter refers to the milling cutter applied to the horizontal milling machine,

but the cutter shaft is parallel to the milling machine table,

and can play a variety of functions in milling processing, with unique characteristics