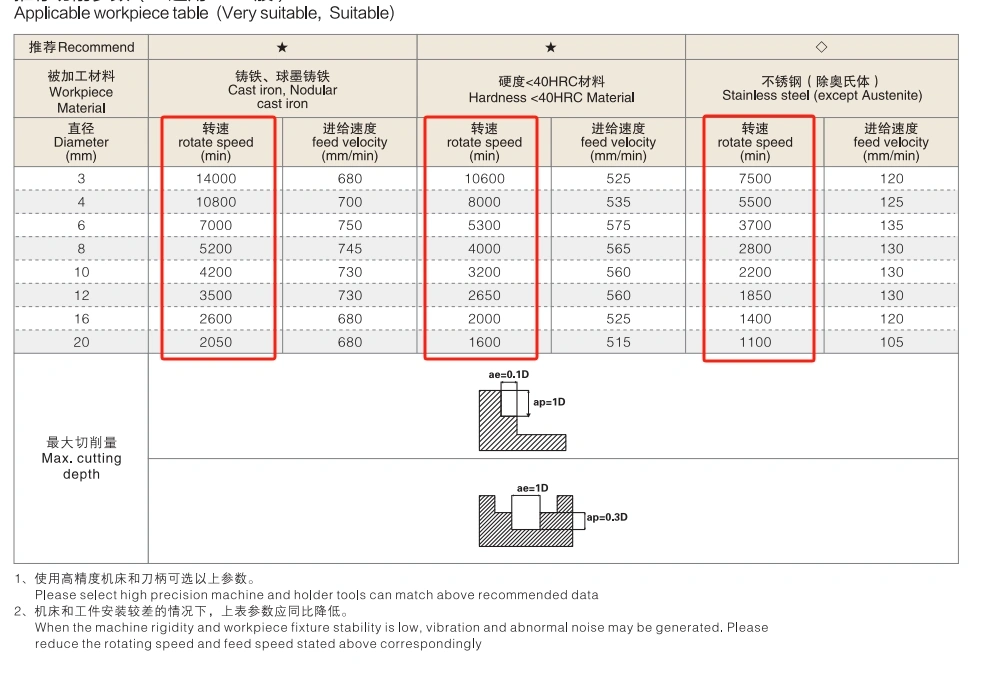

End mill cutting speed and machining feed table

When processing carbide, you must understand the cutting speed diagram, the feed equation, the fast feed formula, the processing speed, and the feed table.

These parameters directly affect processing efficiency, tool life, workpiece surface quality, and cost control.

cutting speed chart:

The cutting speed diagram provides the ideal cutting speed range for workpieces made from different materials with varying hardness levels.

If carbide tools operate at cutting speeds that are either too high or too low, it can negatively impact the machining results.

Therefore, you need to select the appropriate cutting speed based on the cutting speed diagram to ensure proper cutting force and heat control during the machining process.

This will help extend tool life and improve production efficiency.

For example, puwei’s 3-blade flat end mill

End mill cutting speed and End mill cutting rate

feed rate equation:

The feed rate equation determines how much material is removed from the workpiece during each tool revolution.

By calculating the correct feed rate, you can optimize the production process and avoid excessive cutting forces,

which could lead to rapid tool wear or unnecessary heat generation.

Additionally, the feed rate plays a key role in the surface roughness and machining accuracy of the workpiece.

For example, puwei’s 3-blade flat end mill

End mill cutting rate

speed feed formula:

The speed feed formula applies to non-cutting movements or areas where only minimal cutting occurs.

This formula defines the rate at which the tool or machine table moves at a higher speed without cutting.

Understanding the fast feed formula can help you increase the efficiency of non-cutting operations, shorten production cycles, reduce idle time, and improve overall production efficiency.

By applying the correct fast feed speeds, you can ensure quicker transitions between cutting areas, boosting the efficiency of your entire machining process.

Application of Parameters in Lizhou Carbide Tools:

Lizhou’s carbide cutting tools, cutting blades, abrasives, milling cutters, turning tools, and other products provide cutting speed diagrams, feed equations, fast feed formulas, and other technical parameters.

These allow you to choose the right process parameters based on the material type, machining method, and production conditions. This helps optimize production efficiency, extend tool life, and guarantee high-quality machining results.

By utilizing these parameters effectively, you can ensure smoother operations, maximize tool performance, and achieve better quality and cost control in your carbide machining processes.