Efficient machining: Understanding indexable inserts and carbide tools

In the field of mechanical machining, choosing the right carbide tools and inserts directly affects production efficiency and machining quality.

Today, we will take you to understand indexable inserts, carbide tools and their core advantages, helping you to easily cope with complex machining tasks!

一. What are indexable inserts?

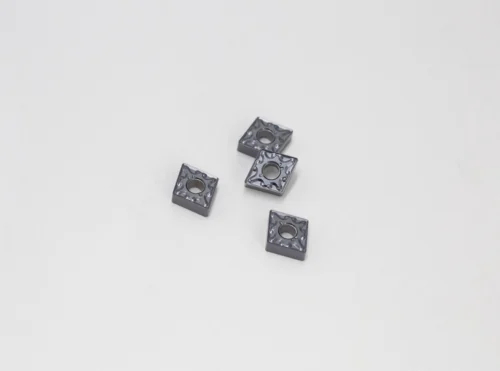

Indexable inserts (also called cutting inserts or inserted blades) are removable, multi-edge inserts that are usually mounted on a tool bar or cutter head.

When a certain edge is worn, the insert can be used again by simply rotating or flipping it, without replacing the entire tool.

This design not only saves time, but also significantly reduces processing costs.

Recommended insert types:

CNMG/TNMG inserts: suitable for rough turning and fine turning, with strong versatility.

WNMG inserts: hexagonal double-sided edge design, longer life.

TiAlN coated inserts: high temperature resistant, suitable for high-speed processing of stainless steel or high-temperature alloys.

二. Advantages of Carbide Tools

Carbide is made of tungsten carbide and cobalt. It has high hardness, wear resistance and high temperature resistance. It is an ideal material for manufacturing cutting tools.

Common tool types:

Turning tools: With Cutter Insert, it can efficiently process shaft or disc parts.

Milling cutters: Use Indexable Insert, suitable for plane milling and contour processing.

Carbide drills: Carbide drill tips can easily penetrate high-strength materials.

Core advantages of Lizhou products:

Long life: 3-5 times more durable than high-speed steel tools.

High efficiency: supports higher speed and feed rate.

Flexibility: By replacing Tool-Tip Insert, one tool bar can meet various processing needs.

三. Applicable materials and processing scenarios

Carbide tools and indexable inserts can process almost all common materials:

Ferrous metals: steel, cast iron, stainless steel.

Nonferrous metals: aluminum alloy, copper alloy.

Difficult-to-process materials: titanium alloy, nickel-based high-temperature alloy.

Recommended processing methods:

Turning: Use CNMG inserts for rough turning of the outer circle and DNMG inserts for fine turning of the end face.

Milling: Select Square Insert for flat surfaces and Round Insert for complex curved surfaces.

Parting: Thin Tool Bit can reduce material waste.

Whether it is mass production or small batch customization, so, indexable inserts and carbide tools can be your right-hand man.

By properly selecting the insert type (such as coating, edge shape) and tool structure, but you can significantly improve processing quality while controlling costs.