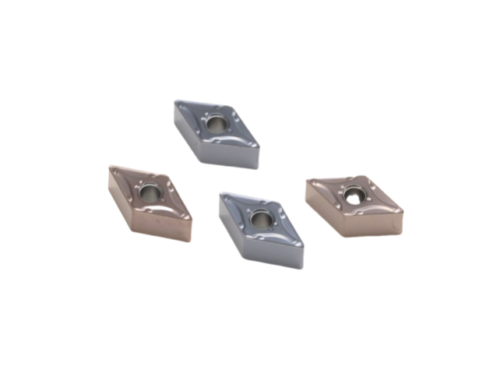

Advantages of stainless steel turning tool DNMG150404-MA

In machining, stainless steel is a material that people both love and hate: it is corrosion-resistant and suitable for high-end parts, but it is easy to stick to the tool, has poor chip breaking, and wears the tool quickly during machining.

Many customers choose DNMG150404-MA or MS chip breaker inserts when batch processing 304, 316, 321 and other stainless steels.

It can not only significantly reduce the problem of sticking, but also improve machining efficiency and surface quality. It is an indispensable “weapon” in stainless steel machining.

1、What is turning tool DNMG150404?

Let’s take a quick look at the meaning of the model:

D: 80° diamond shape, strong versatility, both rigidity and sharpness

N: 0° back angle, suitable for rigid processing

M: medium precision level

G: double-sided blade, 6 cutting edges

150404: side length 15.875mm, thickness 4.76mm, cutting edge radius 0.4mm

DNMG blades combine the flexibility of TNMG and the stability of SNMG, and are particularly suitable for stainless steel processing under medium loads.

2、DNMG150404 has three advantages in processing stainless steel

1. Smooth chip breaking and prevention of tool sticking

Stainless steel easily forms built-up edge on the blade surface, affecting the cutting quality. DNMG150404-MS/MA is equipped with a chip breaker designed specifically for stainless steel, which makes chip removal smooth, effectively prevents tool sticking, and makes the processing process more stable.

2. Reasonable tool tip angle and strong versatility

DNMG’s 80° tool tip angle is blunter than VNMG’s 35° and TNMG’s 60°. While maintaining the cutting sharpness, it also improves the strength and anti-breakage ability of the tool tip. Very suitable for long-term, batch stainless steel processing.

3. Multi-tip structure, high cost performance

A DNMG150404 turning tool has 6 available tool tips, which are easy to replace and have high utilization rate. It is more economical than precision integral tools and is particularly suitable for daily use in medium and large turning factories.

3、Comparison between DNMG150404 and other turning tool (TNMG, VNMG, SNMG)

| Insert model | Features | Processing suitability |

| TNMG | 60° triangle, flexible and versatile, 6 tips | Strong versatility, suitable for carbon steel, cast iron, etc. |

| VNMG | 35° sharp angle, suitable for profiling and finishing | Small parts, fine contour stainless steel parts |

| SNMG | Square, strong rigidity, 8 cutting edges, suitable for rough machining | Heavy load, interrupted cutting (such as cast iron) |

| DNMG | 80° angle, rigid and flexible, stable chip removal | ✔ Ideal for processing stainless steel |

Conclusion:

If you need a blade that is stable and not prone to chipping on stainless steel, the DNMG150404 is an ideal choice.

4. Why choose DNMG150404 of Puwei Cemented Carbide?

Choosing Puwei means choosing more reliable product quality and service support:

Self-developed alloy materials, more wear-resistant and heat-resistant

A variety of groove types are available (MS/MA/MP) to meet different cutting needs

Sufficient stock, support fast delivery, save waiting time

Customizable brand LOGO and packaging, support OEM/ODM

Products are exported to 20+ countries and have a good reputation among customers

5. To sum up, what are the core advantages of DNMG150404 for processing stainless steel?

Non-stick knife, smooth chip breaking

Strong knife tip, suitable for long-term cutting

High-quality coating, long service life

Reasonable cost, high cost performance

Strong adaptability to working conditions, suitable for mass production