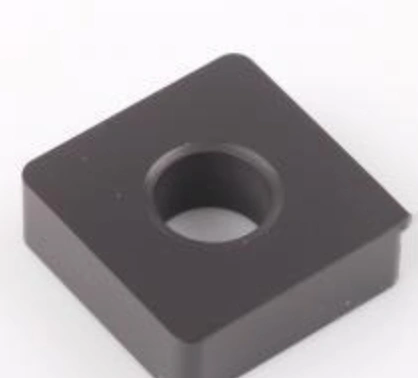

Advantages of machining stainless steel turning insert SNMG120408

In machining, stainless steel has always been considered a difficult material to machine used lathe insert. It has strong toughness and poor thermal conductivity, and is prone to problems such as tool sticking, built-up edge, and rapid wear.

So, how can you easily handle stainless steel? The answer is simple – choose SNMG120408-MS/MA stainless steel special turning inserts!

What is SNMG120408?

Let’s quickly understand what this model means:

S: square blade, four 90° cutting edges, stable and durable

N: 0° back angle, suitable for heavy load and rough machining

M: medium precision

G: double-sided with holes, both sides can be used

120408: side length 12mm, thickness 4.76mm, cutting edge radius 0.8mm

When the suffix is MS or MA, it means that this is a chip breaker designed for 304 steel, with better chip evacuation performance and wear resistance.

Comparison between lathe insert SNMG and TNMG for cast iron

| Compare Projects | TNMG-HK(cast iron) | SNMG-MS/MA(Stainless steel) |

| Material characteristics | High hardness, resistant to abrasive wear | High toughness, resistant to adhesion and wear |

| coating | CVDThick film, more wear-resistant | PVDNano coating, heat-resistant and anti-stick |

| Insert shape | Triangular, 6 tips | Square, 8 tips |

| Cutting characteristics | Good chip breaking for brittle materials | Smooth chipping of tough materials |

| Whether to swap | ❌ Not recommended | ✅ Optimized for stainless steel |

| Applicable Materials | Gray cast iron, ductile iron | 304, 316, 321, duplex stainless steel |

To sum up in one sentence: TNMG for cast iron pursues wear resistance, while SNMG for 304 steel pursues anti-sticking and high temperature resistance.

SNMG lathe inserts are suitable for materials:

| Material Category | Applicable | Recommended instructions |

| Stainless steel | ✅ Highly recommended | With MS/MA chip breaker, anti-sticking, wear-resistant, good chip breaking |

| cast iron | ✅ Very suitable for | With HK chip breaker, high rigidity, chipping resistance, suitable for intermittent machining |

| Carbon steel/Alloy steel | ✅ Suitable | With GP/MP geometry, for roughing to semi-finishing |

| High temperature alloy | ⚠ Optional | When conditions are right, use special materials and coatings |

| Aluminum alloy/non-ferrous metal | ❌ Not recommended | Positive rake blades are more suitable |

turning insert SNMG is particularly suitable for these working conditions:

Stainless steel processing:

For high-toughness materials (such as 304, 316, 321, duplex stainless steel), SNMG can effectively avoid sticking and break chips smoothly, especially suitable for heavy load and rough processing.

Cast iron processing:

For gray cast iron and ductile iron, SNMG has better anti-breakage performance and is very suitable for dry high-speed cutting and intermittent processing.

Alloy steel/carbon steel processing:

When facing heavy load and large cutting depth processing, lathe insert SNMG can ensure the stability of the processing process with its super rigidity brought by the 0° back angle

lathe insert SNMG Summary:

If you want to process 304 steel, choose SNMG with MS/MA chip breaker, which is very suitable.

If you want to process cast iron, choose SNMG with HK chip breaker, which also performs very well.

If your working conditions are high feed, heavy roughing, and interrupted cutting, SNMG inserts are almost invincible.