Face milling cutter machining steel parts

In the steel processing workshop, efficiency and cost matter a great deal. The surface milling cutter is vital. It can quickly and precisely remove excess from steel surfaces during machining, like when dealing with alloy steels.

By rotating at high speed for efficient cutting, it shortens processing time. For large steel plates, it ensures a smooth finish while speeding up production, thus reducing per – unit costs.

We design our face milling cutters with a solid carbide cutter body and optimize the spiral angle parameters for common steels such as S45C and 40Cr.

Measured in the Φ100mm cutter head configuration, a single tool can achieve a 5mm depth of stable cutting, with high-speed milling machine surface tool drive system, so that large area surface processing efficiency increased by more than 30%.

What is a indexable face mill?

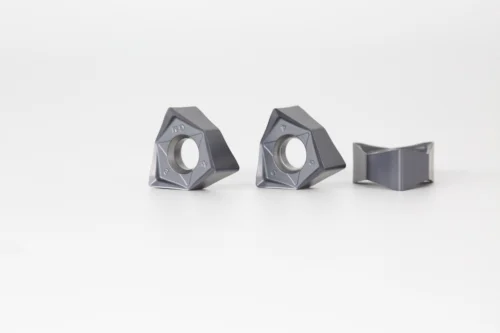

Indexable Face Mills are efficient milling tools that manufacturers commonly use in CNC machining. Their core feature is the ability to quickly replace or turn over the blades for use. The main structure consists of two parts:

Cutter body + blade combination design:

- High-strength alloy steel blade body: with precision design of the blade mounting slot (common wedge locking, screw fixed structure)

- Indexable blade: carbide material, double-sided or polygonal multi-cutting edge design (such as octagonal blade can provide 16 effective cutting edges)

the increasingly fierce competition in the manufacturing industry, cost control and processing efficiency have become the key factors for enterprise development.

An auto parts factory in Zhejiang, China, faces the challenge of reducing costs and improving efficiency in the production process.

In the processing of Q345 steel plate this key link, the factory selected Φ125mm indexable face milling cutter.

This type of face milling cutter shows excellent performance, and in practice, each milling machine face cutter can continue to be used by transposing after the completion of 120 pieces.

This clever design makes the service life of the tool greatly extended. Compared with traditional tools, the factory has achieved a significant reduction in the cost of a single tool, saving a lot of money for the enterprise, effectively enhancing the market competitiveness of the product, and also providing a valuable reference example for the same industry in the selection and use of tools.

If you are interested in our face mill blades, please scan the code and join our WhatsApp. We can keep in touch with you at any time.